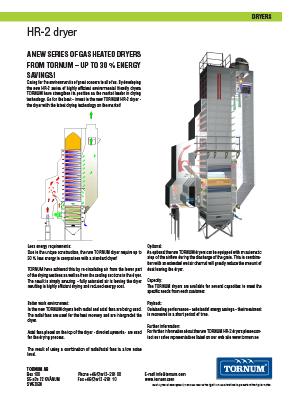

Product Description

Tornum’s HR (Heat Recovery) grain dryer is the result of our ongoing efforts to develop our product range to reduce the energy consumption and thereby the environmental impact. The HR grain dryer makes use of the energy that would be lost in a traditional grain dryer. Normally, up to 30 percent of the heat is recovered. The unique HR design also provides a quieter and cleaner work environment. As all Tornum grain dryers, the HR series is made from hot-dip galvanized sheet steel.

STANDARD EQUIPMENT

• Level indicator

• Wet air plenum

• Discharge section – pulse

• Level sensor

• Buffer zone

• Fire detection system

• Ladders and platforms

• Recovery zone

• Control moisture content

• Pressure measurement for adjusting start-up

Reduces energy consumption by up to 30 percent

Around a quarter of the hottest air in a HR grain dryer is recirculated. Recovered air is passed through a recirculation zone and then mixed with the heated cooling air. As the recycled air is warmer than the ambient air, you can reduce the energy supply for the gas burner (compared to using only fresh air) and still reach the desired drying temperature. The design of the HR dryer also means that the exhaust fans at the top of the grain dryer require less Power. Watch a movie at Youtube to check out the air flow in the dryer.

OPTIONS

• Increased buffer zone

• Dust separation including discharge auger

• Silencer